Post-Analysis Consolidation of Ceramics and Pottery

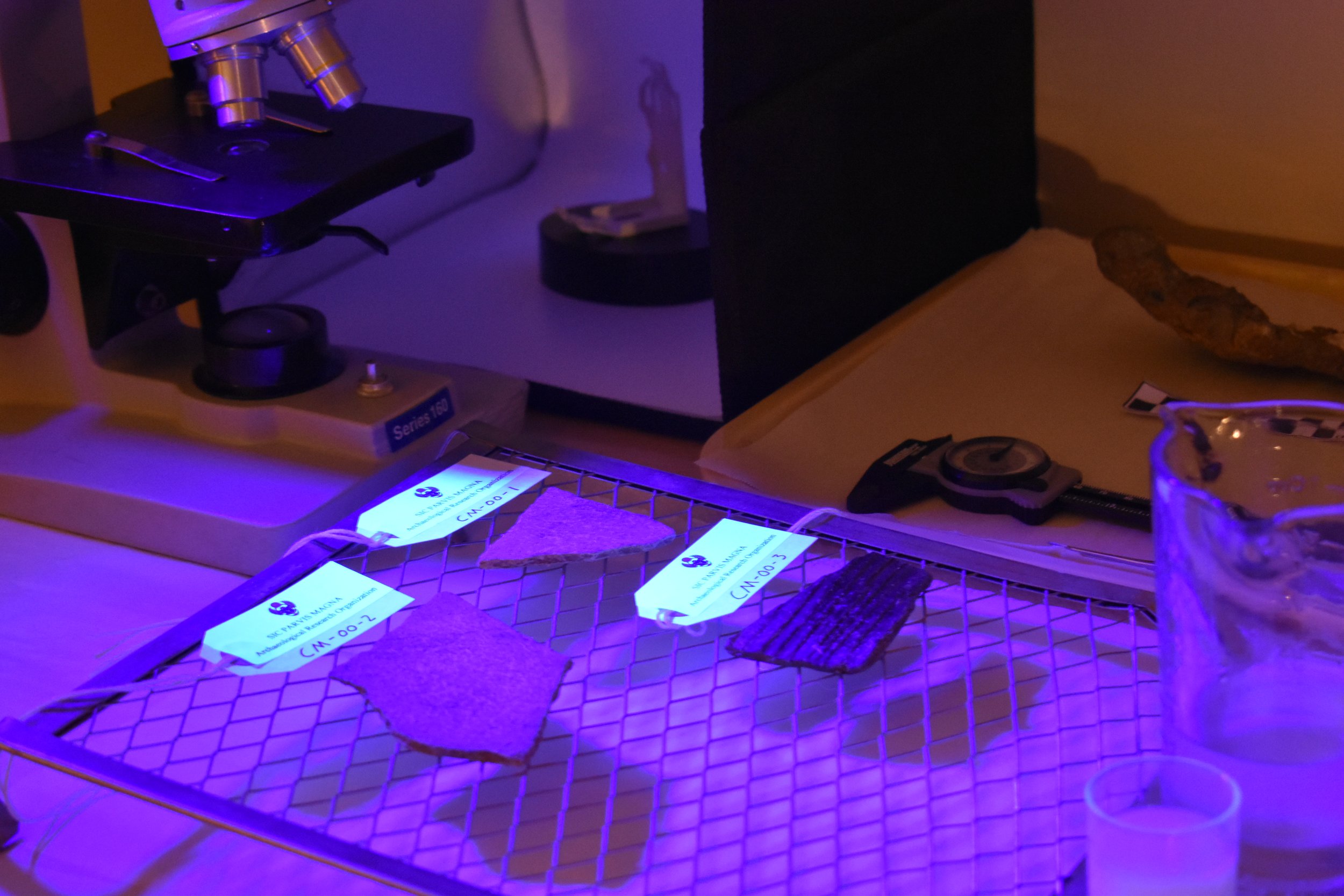

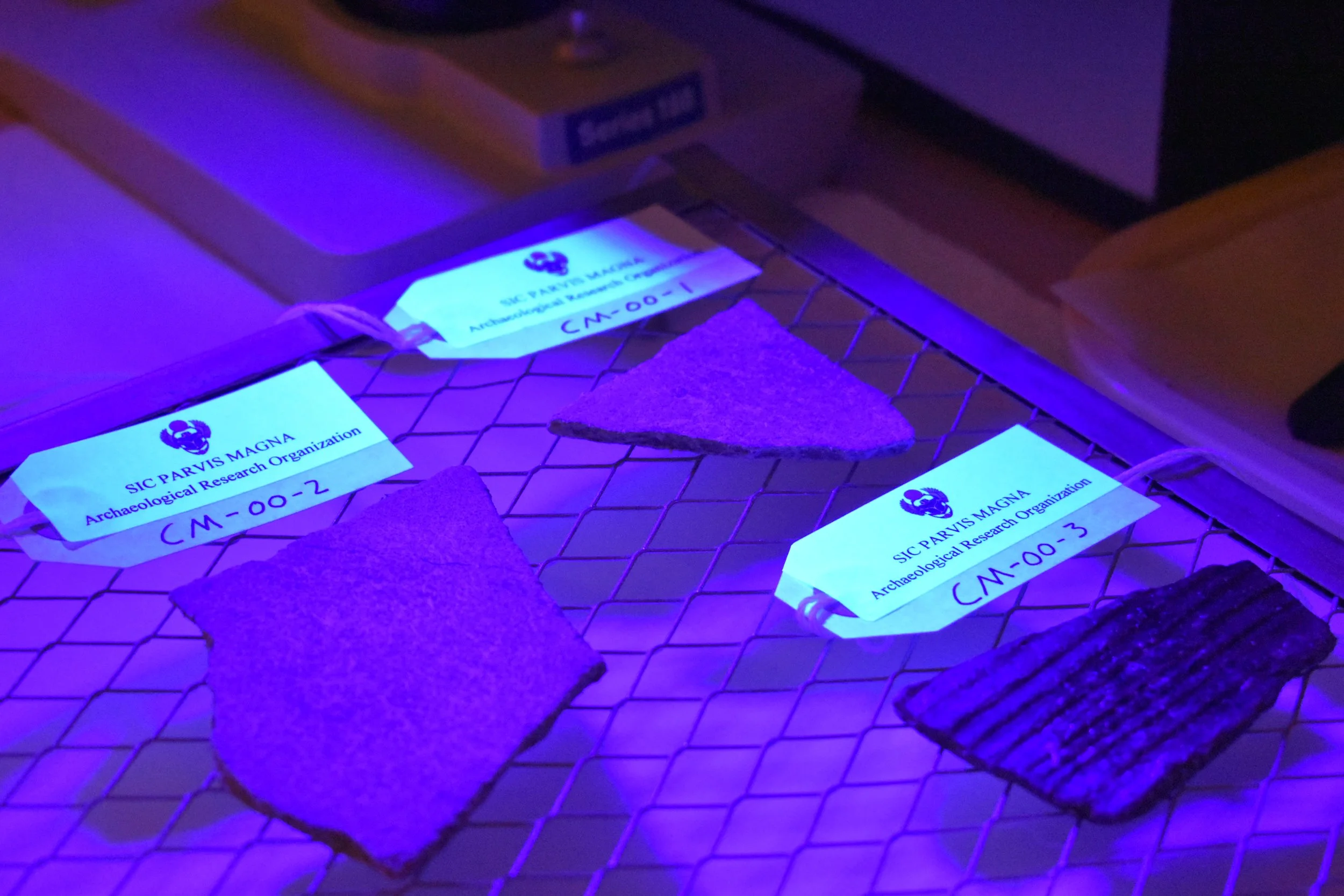

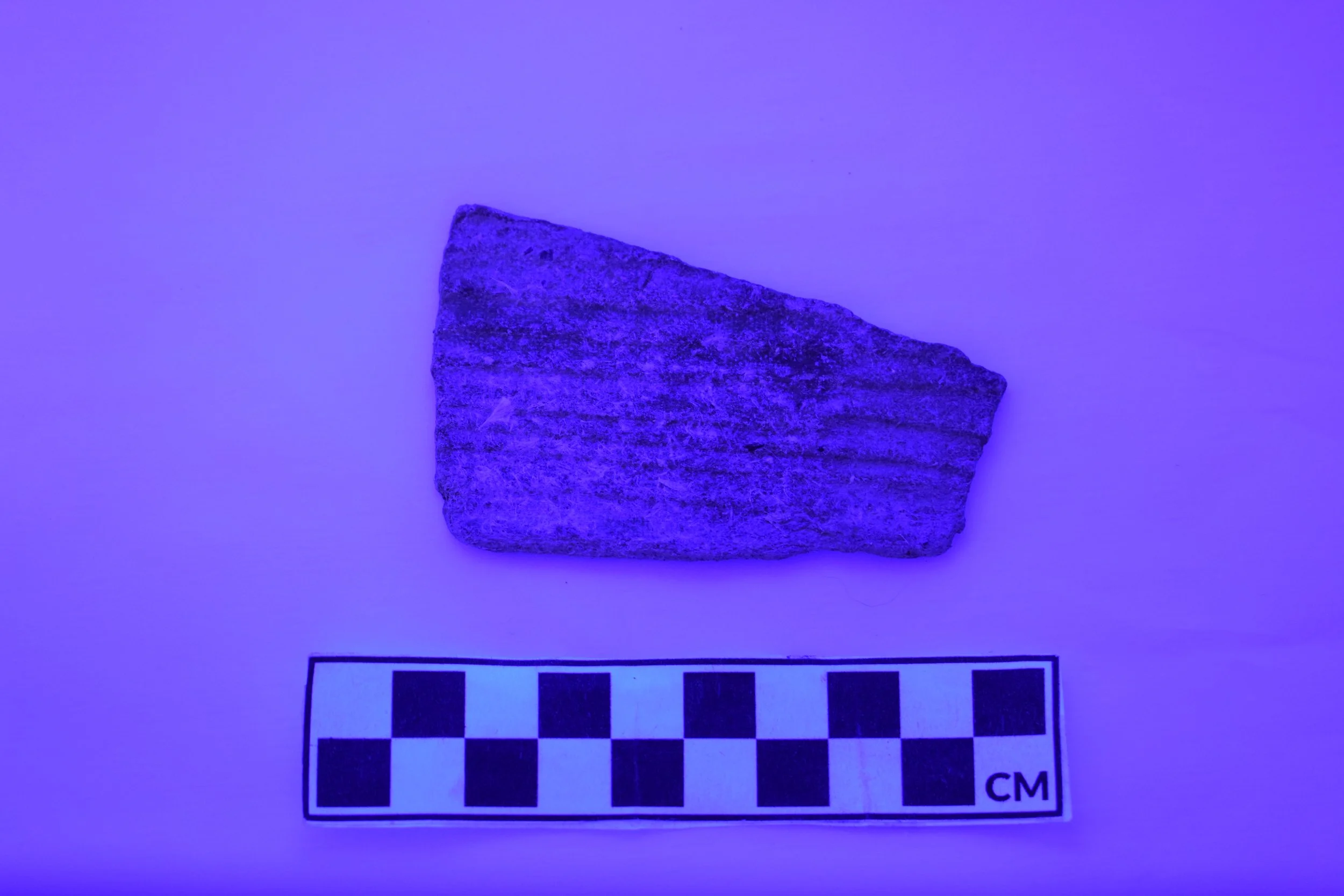

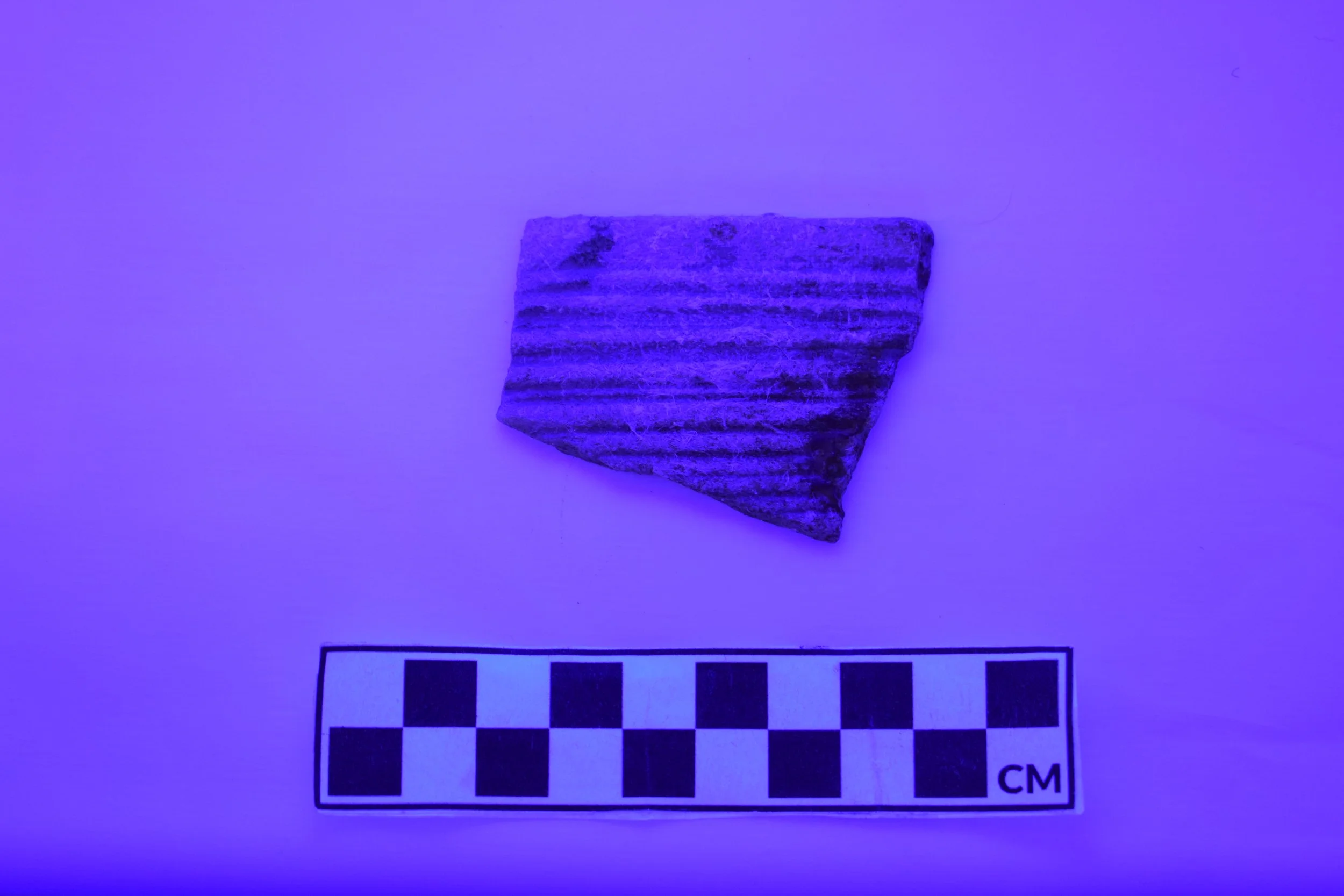

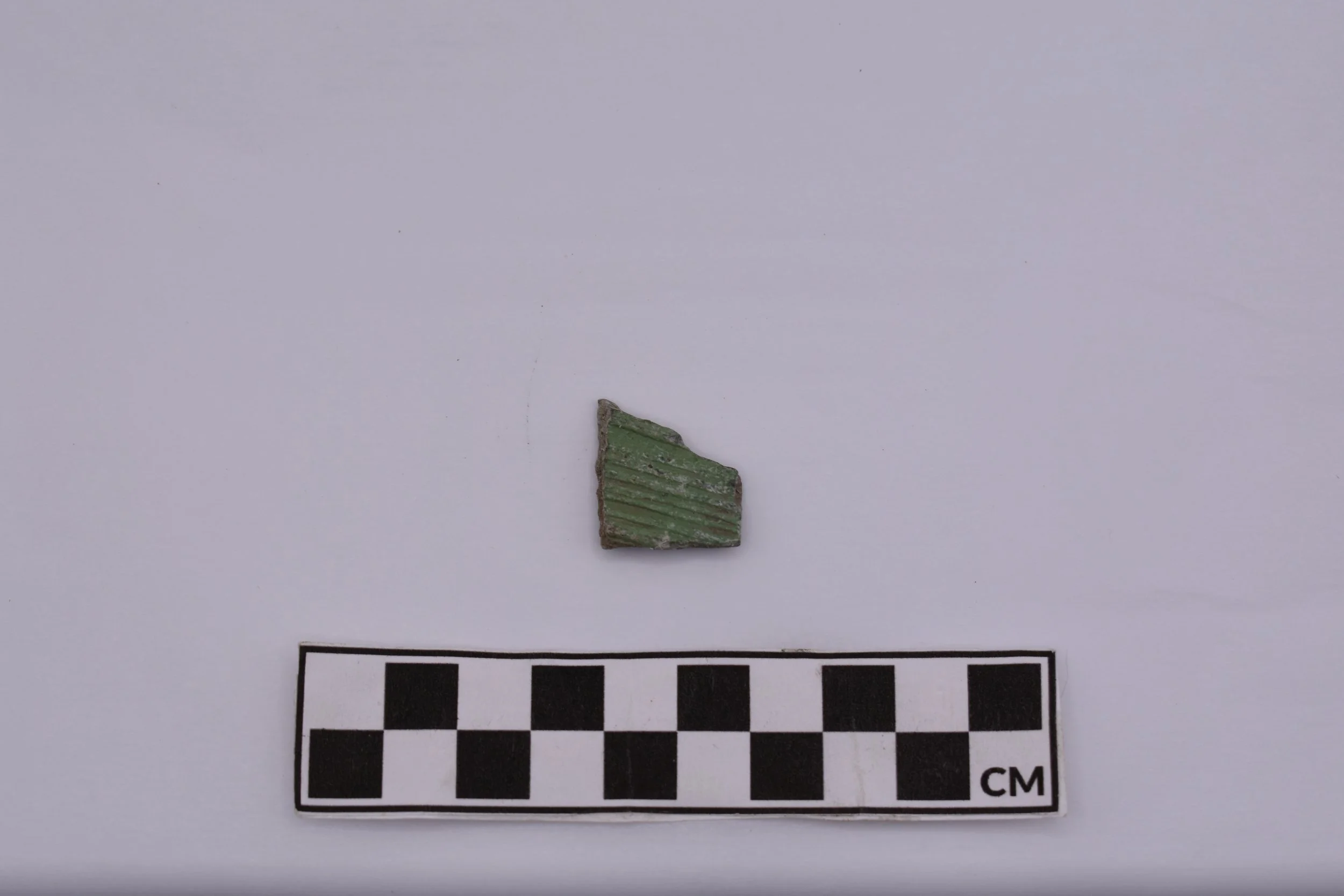

Now that the ceramicware and pottery recovered from July’s recovery has been properly processed and documented through the lab, they can be consolidated in a resin for storage until further analysis is required. Each friable ceramic, pottery sherd, and earthenware artifact will be lacquered using an aqueous solution of 10% polyvinyl acetate-polyvinyl alcohol-propylene glycol emulsion. This solution will protect the artifact from the oxidizing environment, and it’s viscosity is thin enough to allow it to pass through permeable surface layers in the artifact. They will then be cured with a high-energy wavelength lamp set at 395 nanometers for roughly 45 minutes, or until an unyielding clear glaze sets (fig. I). Once dried, the resin will reinforce the friable nature of the pottery or ceramic, and maintain its authenticity from the marine environment it was recovered from.

Figure I

Due to the common friability of many different types of ceramicware and pottery recovered from marine environments, it is important to keep them wet through the conservation process and ensure a plan of action before recovery. There is a small window of time the conserving technician must act in to keep the artifact from degrading in the ambient environment.